Parkhaus Berlin - Hochwertige Filzauflagen für Designklassiker

€66.70* €38.00*

In stock

€50.30* €32.00*

In stock

€43.00* €29.00*

In stock

€131.00* €65.00*

In stock

€150.00* €89.00*

In stock

€96.00* €82.00*

In stock

€116.00* €99.00*

In stock

€131.00* €74.00*

In stock

€50.00* €43.00*

In stock

For more seating comfort in the stylish home

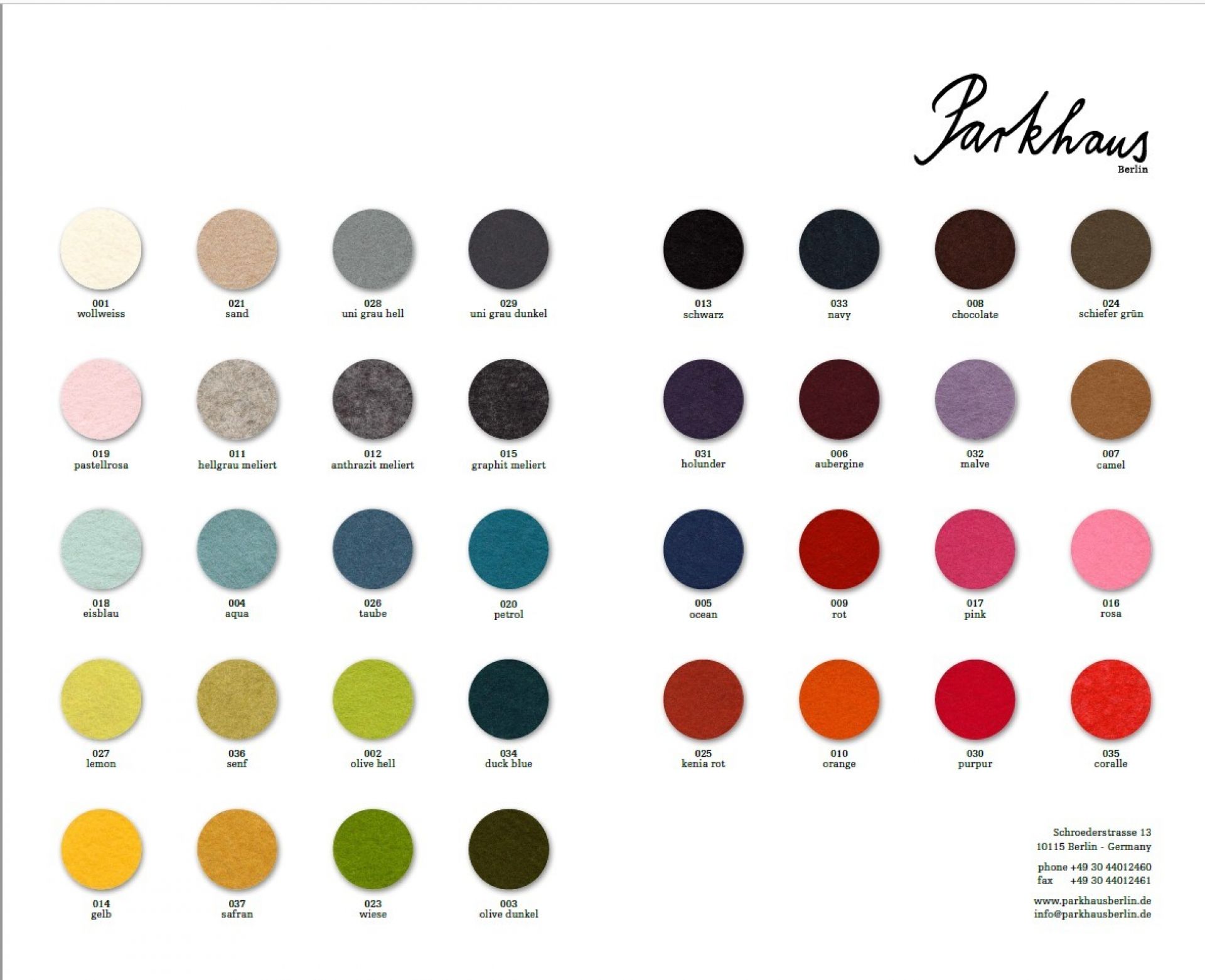

Since its founding in 2002 by product designer Anja Witte-Krieger, PARKHAUS Berlin has developed into a leading manufacturer of high-quality felt cushions for numerous design classics. With an extensive range of cushions, the company manufactures cushions for over 100 classic design chairs from renowned brands such as VITRA, Thonet, Kartell and many more.

Among the well-known models for which Parkhaus Berlin produces felt cushions are some of the most iconic chairs in design history. For example, the famous Eames Plastic Chair chairs in the versions DSR, DSW, DAR, DAW as well as the Panton Chair by Vitra and the Louis Ghost by Philippe Starck. The unusual felt covers not only give these pieces of furniture an additional aesthetic touch, but also offer practical benefits in the form of comfort and functionality.

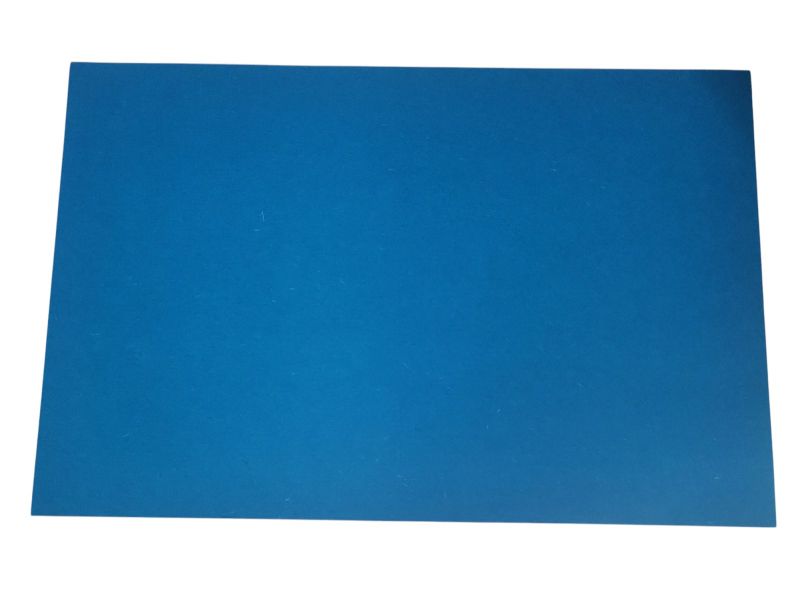

Parkhaus Berlin attaches particular importance to the quality of its products. The felt pads are made of 100 % wool felt and are given a special anti-slip coating to ensure that they sit firmly and securely on the design classics. Wool felt is a remarkable material with outstanding properties. It insulates excellently against heat and cold, is air-permeable, dampens vibrations, is dirt-repellent, absorbs odours, is flame-retardant and is also kind to the skin. This makes the felt cushions from Parkhaus Berlin a real super talent in the world of seating.

Another important aspect that distinguishes the products from Parkhaus Berlin is their origin. The wool felt used is made in Germany, while the wool comes from Australia and New Zealand. The careful production of the felt is an elaborate process that uses water, soap, heat and pressure to felt, mill, sand and dye the wool. The result is a unique and high-quality material that can not only be seen, but above all felt.